By: Katie Tich, LEED AP BD+C, GGP

Last week’s blog post explored the environmental impact of cement and some structural strategies we can use in the built environment to reduce that impact. This week, the conversation continues with information about cement alternatives and a discussion about the utility of carbon mineralization to lessen concrete’s carbon footprint.

Reducing Cement: Replacements and SCMs

The most straightforward way to limit the carbon emissions from concrete is to find ways to use less cement. Reducing the amount of cement in concrete can drastically cut the emissions associated with its production, and replacing some of the cement in a concrete mix with other materials can make a huge difference. Fly ash, a byproduct of coal combustion, and blast furnace slag, a byproduct of iron production, are two of the most common supplementary cementitious materials (SCMs). These materials offer both structural and environmental benefits. Fly ash and slag both increase the set time of concrete, but also improve its durability and workability, reduce the amount of water needed for the concrete mix, and improve the ultimate strength [1]. SCMs like fly ash and slag also decrease the cost of concrete, making them an attractive financial option for projects looking to decrease carbon emissions and save money.

Carbon Mineralization – The Future?

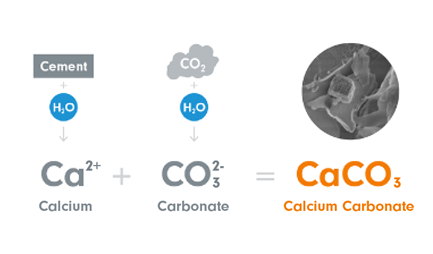

An innovative technique for mitigating carbon emissions from concrete has been gaining steam in the construction industry – capturing carbon emissions and injecting them back into concrete itself. With a little help from some simple chemistry, carbon dioxide can transform from a harmful greenhouse gas into a solid mineral, calcium carbonate, which has high compressive strength like concrete [2]. It turns out this chemical reaction is perfectly suited for concrete, since cement has the exact substance needed – calcium – to mineralize carbon dioxide (CO2).

CarbonCure is the leading company in the industry producing carbon-capturing concrete. To perform this process, CarbonCure sources carbon dioxide recovered from industrial gas supply companies by carbon capture facilities across the globe. These capture facilities prevent the CO2 from entering the atmosphere, condense, and dry it, and purify it before selling it for reuse. When CarbonCure purchases the CO2, it is injected from a CO2 storage tank into wet concrete during mixing [3]. When the CO2 interacts with the calcium ions in cement, it forms CaCO3, or calcium carbonate:

Once the reaction is complete, the calcium carbonate becomes embedded into the concrete. It supports the compressive strength and reduces both the amount of cement required and the material cost. The best part about mineralization technologies like CarbonCure is that they do not simply sequester CO2 away in concrete to be dealt with when the concrete is eventually demolished – they use chemistry to transform what was once CO2 into a different compound entirely [4]. When the concrete with embedded calcium carbonate is demolished at the end of its life, it can be recycled easily, since old concrete can be crushed and reused as aggregate for new concrete. The new concrete can be injected with carbon dioxide again, just as it was in its first life.

Carbon mineralization, like all the other carbon mitigation efforts outlined here, is not a silver bullet to solve climate change. Concrete like CarbonCure still requires cement, and the environmental effects of storing and transporting the large amounts of CO2 required for the mineralization process at scale are unquantified [5]. However, technologies like CarbonCure represent a crucial step in the process of implementing a fully circular economy. Since concrete is 100% recyclable, figuring out how to implement CO2 mineralization effectively and efficiently on a larger scale could be the key to a future where the concrete industry is carbon-negative and zero-waste.

Advocating for Change

What can we do in the industry to help implement these strategies and reduce the carbon footprint of cement? The biggest way to make an impact is for everyone to normalize carbon reduction methods. Concrete manufacturers can take advantage of cost savings by reducing the cement content of mixes and adding SCMs or injecting waste carbon to add strength. Architects and contractors can design structures using lower-carbon concrete, and source their concrete from manufacturers who actively work towards improving concrete sustainability. Owners and developers can require the use of low-carbon concrete in their project requirements and specifications. The more we can promote the use of low-carbon concrete, the greater the positive environmental impact it will have – so let’s get started.

[1]https://www.fhwa.dot.gov/pavement/recycling/fach03.cfm#:~:text=Replacing%20cement%20with%20the%20same,problems%20in%20mass%20concrete%20placements

[2] https://www.carboncure.com/concrete-corner/introducing-carboncure-for-precast/#:~:text=CarbonCure%20for%20Precast%20works%20by,cement%20content%20in%20mix%20designs

[3] https://www.carboncure.com/concrete-corner/the-lowdown-on-carboncures-co%E2%82%82-supply/

[4] https://www.carboncure.com/concrete-corner/the-lowdown-on-carboncures-co%E2%82%82-supply/

[5]https://www.ncbi.nlm.nih.gov/books/NBK541437/#:~:text=Moreover%2C%20scaling%20up%20ex%20situ,costs%20and%20unknown%20environmental%20impacts